Your cart is empty

Friction Tuck

- Top loaded design.

- The fixing structure utilizes the erosion between the slit lock between the tongue, dust fold, and the panels to create a closing.

- It is one of the most widely recognized closure structures for box styles.

- Medium level strength

- Appropriate for little, lightweight things, for example, everyday necessities in pharmaceutical packaging.

Seal End

- End loaded design

- the structures are panels, sealed to the glue, and attached the flaps with the base box that adhere together.

- The Locking solidity and reliability of the seal ensure that the things or content which is inside are secure and untouched.

- the structure style has a glue seal which is less suitable but it is perfect for industries with programmed packaging lines such as food industries.

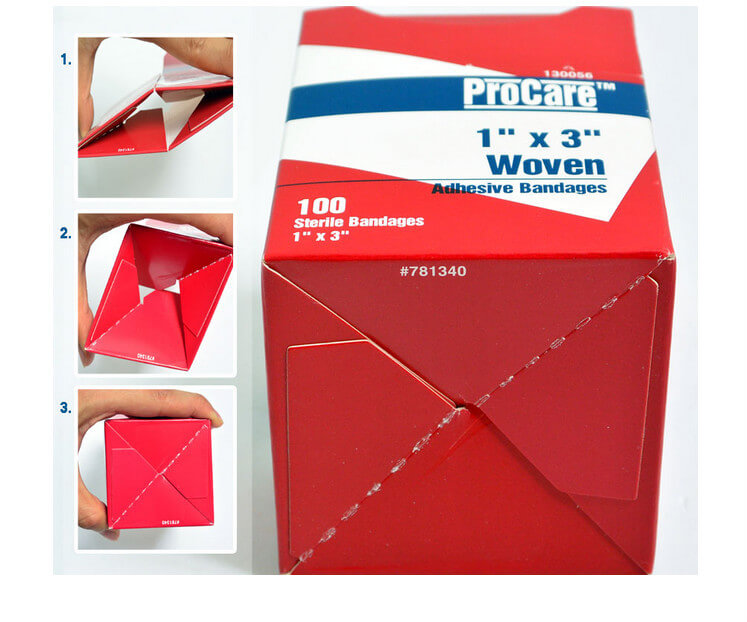

Snap lock bottom

- Top loaded design

- The snap-lock bottom is also referred to as 1-2-3. Which points to the three steps of completing the closure, which makes it easy for assembly.

- Simple structure and base closure are ideal for the heavier products to be packaged with all your desired customization you choose for your brand exposure.

- It is an economic option that retains strength and tiredness in the closure.

- It is a low-cost and economical option for large volume orders.

- Snap lock bottom boxes are used for many categories such as cosmetic or food products.

Automatic lock bottom.

- The automatic lock bottom points to the box base and body that can be molded into a nice and flat plate for compatibility.

- These boxes have a sophisticated structural design with a bottom that gets locked automatically when squeezed.

- The structure is a little complex so, it cost higher then the other boxes •These boxes are perfect for the big orders such as 10,000 cartons.

- It is a top-loaded design and ideal for small food and beverage products including tea or coffee bags.

6 corner glued

- Top loaded Design

- This is quite similar to 4 corners glued, it features 4 glued flaps on the bottom of the box whereas the remaining 2 are located on the lid.

- It is easier to assemble by hand and doesn’t need a higher unit cost as it is costly and only need a complex glue set up

- It is ideal for the muffins, pastries, gifts, and other goodies.

4 corner glued

- Top loaded design

- It is built with rigid and sturdy material.

- It has the finest stackability with double layers on every side (3)

- All the corners are glued before the setup time when being packed to reduce time.

- This box has an expensive rate as it has a complex glue set up and slower run speed.

- They are ideal for gift products and pastries.